Products

Design is the intermediary between

information and understanding

" Product design / CAD Drafting & 3D Modelling — Nova-Tech"

While specific methods may vary, most product design follows a multi-stage, iterative process grounded in design thinking. A common approach includes:

- Research: Conduct market and user research to understand the target audience's needs, behaviors, and existing market solutions. This includes creating user personas and journey maps.

- Ideation: Brainstorm and generate a wide range of potential solutions based on the research findings. Techniques like mind-mapping and storyboarding are common in this stage.

- Prototyping: Create a working model of the potential solution, from low-fidelity paper sketches to high-fidelity interactive versions. This allows teams to test functionality and viability.

- Testing and validation: Test the prototype with real users to collect feedback on its usability and effectiveness. This data is critical for refining the design.

- Launch and iteration: Release the final product to the market. Good design continues post-launch by monitoring performance and iterating on the product based on user feedback and data

<< Scroll below, for more slides >>

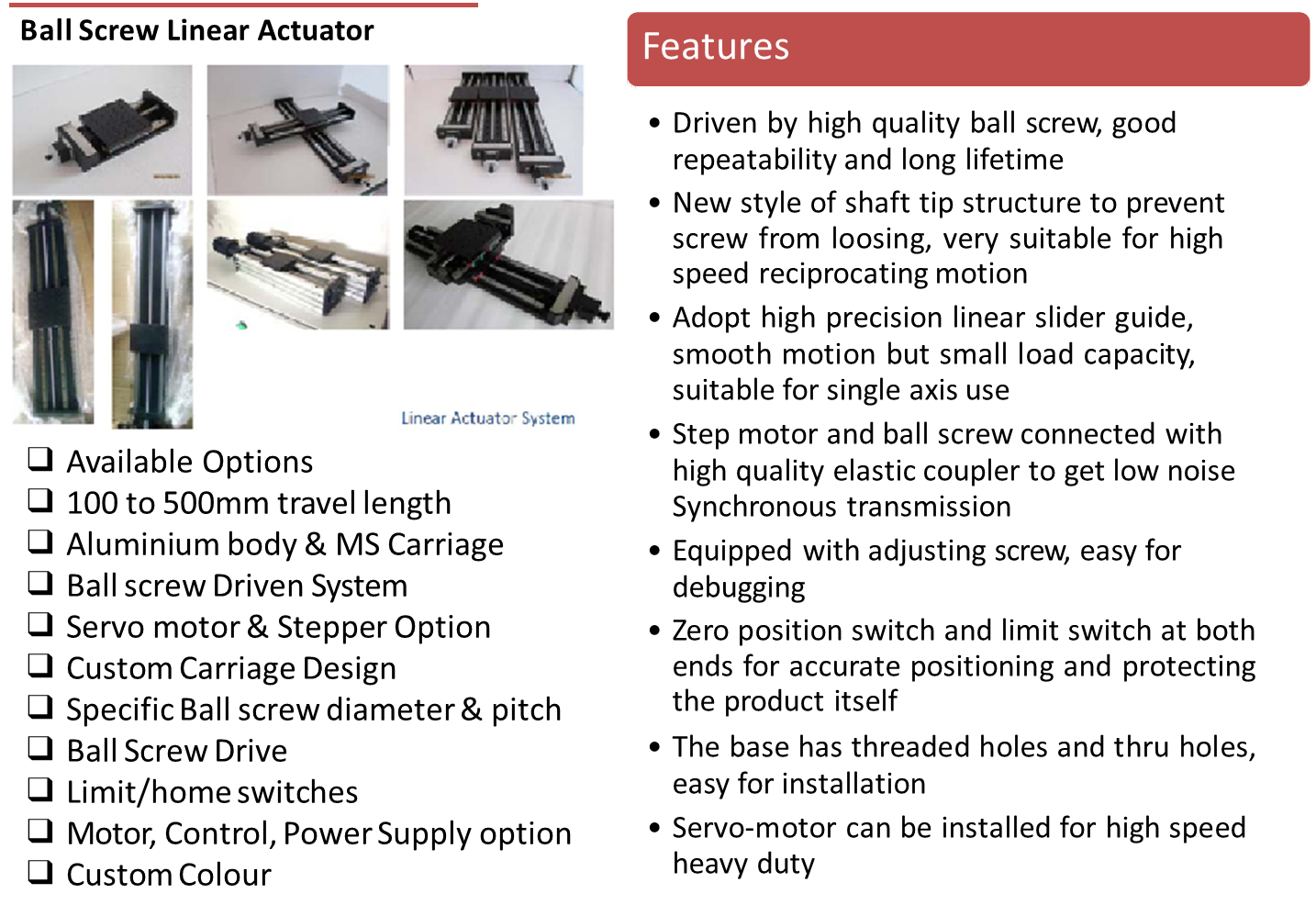

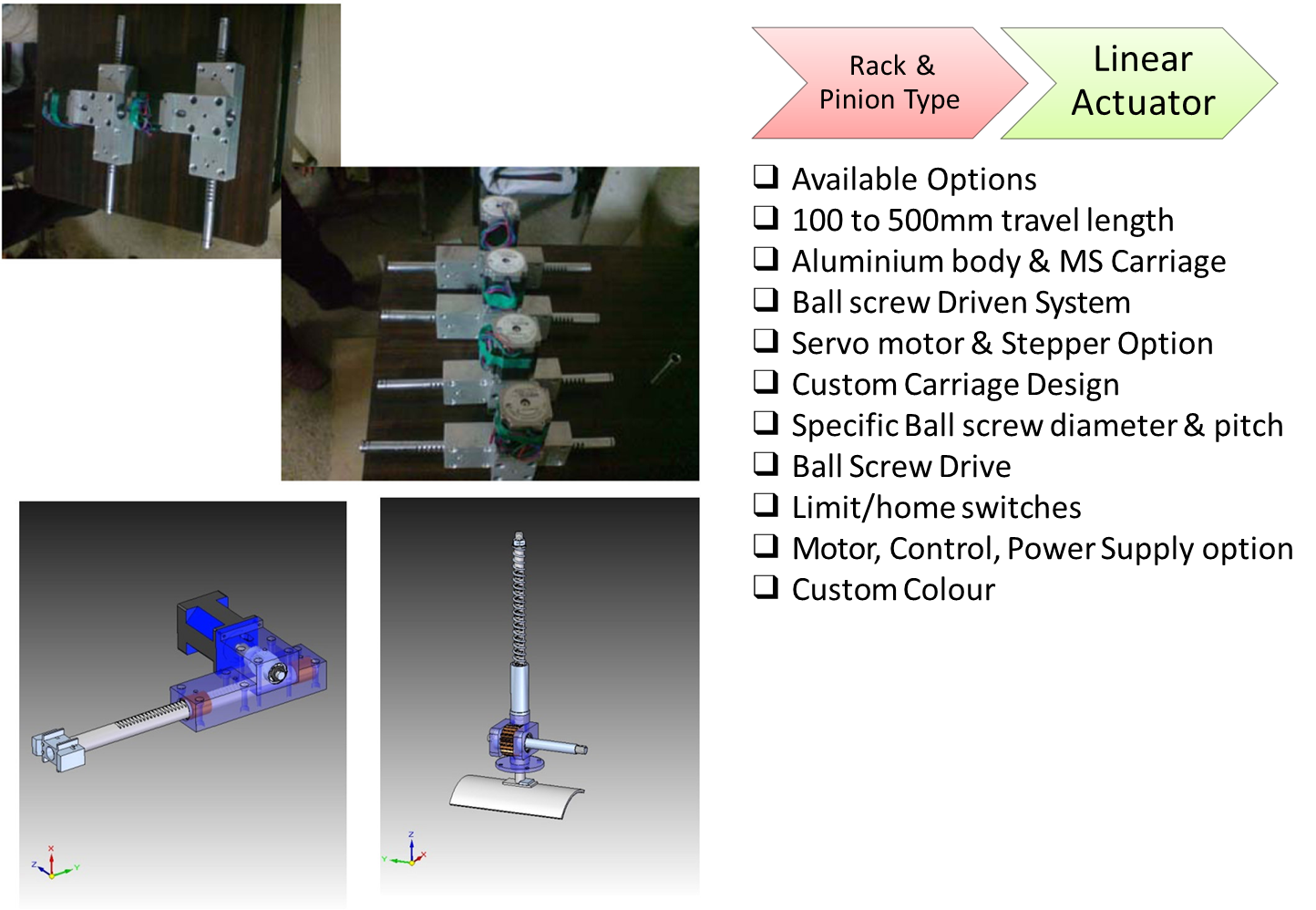

Ball Screw & Linear Actuator

Lead Screw Actuator

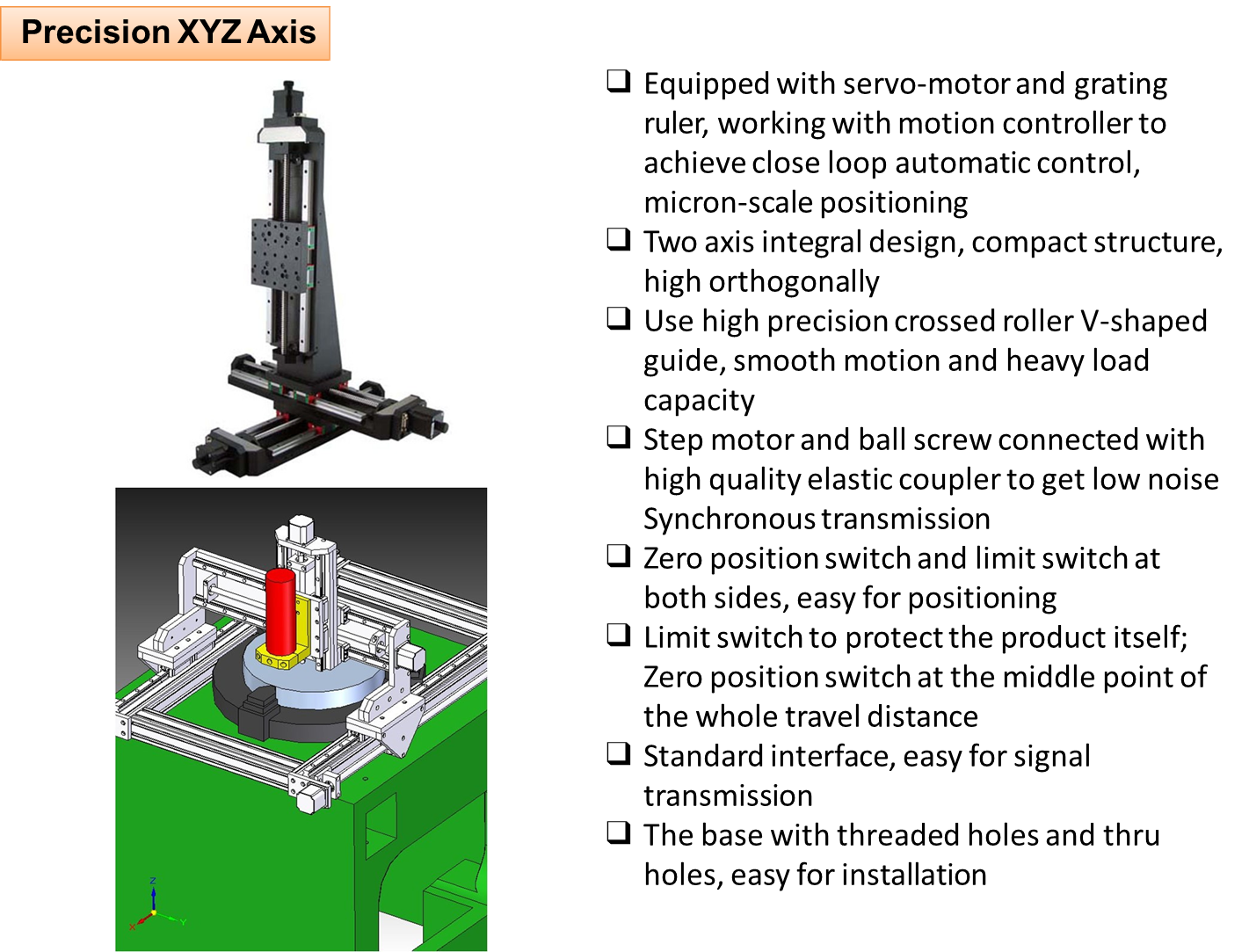

Precision XY SLides

Precision XY Slides

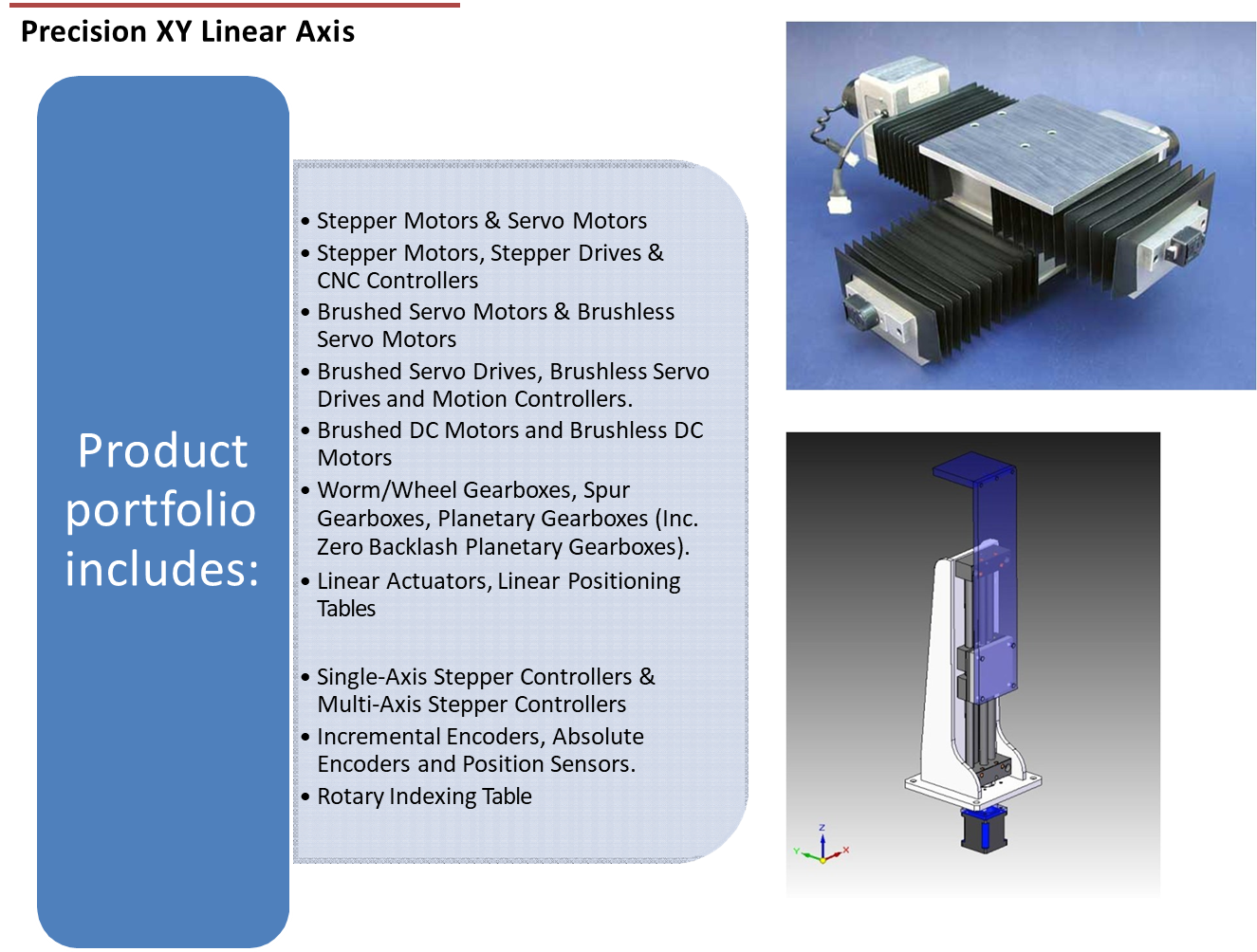

Precision XY Linear Axis

" Special Purpose Machines (SPMs) — Nova-Tech "

The machine design process involves defining requirements, followed by conceptualizing and detailed design, including material selection and component design. This is followed by analysis and simulation to ensure functionality, then prototype testing and validation. Finally, the design is manufactured, assembled, and undergoes quality assurance before deployment.

The design process is typically approached in these seven steps:

- Define the problem. You can begin solving any design problem by asking the right questions. ...

- Conduct research. ...

- Brainstorm and conceptualize. ...

- Create a prototype. ...

- Select and finalize. ...

- Product analysis. ...

- Improve

<< Scroll below, for more slides >>

Quilt Stitching machine XYZ Axis

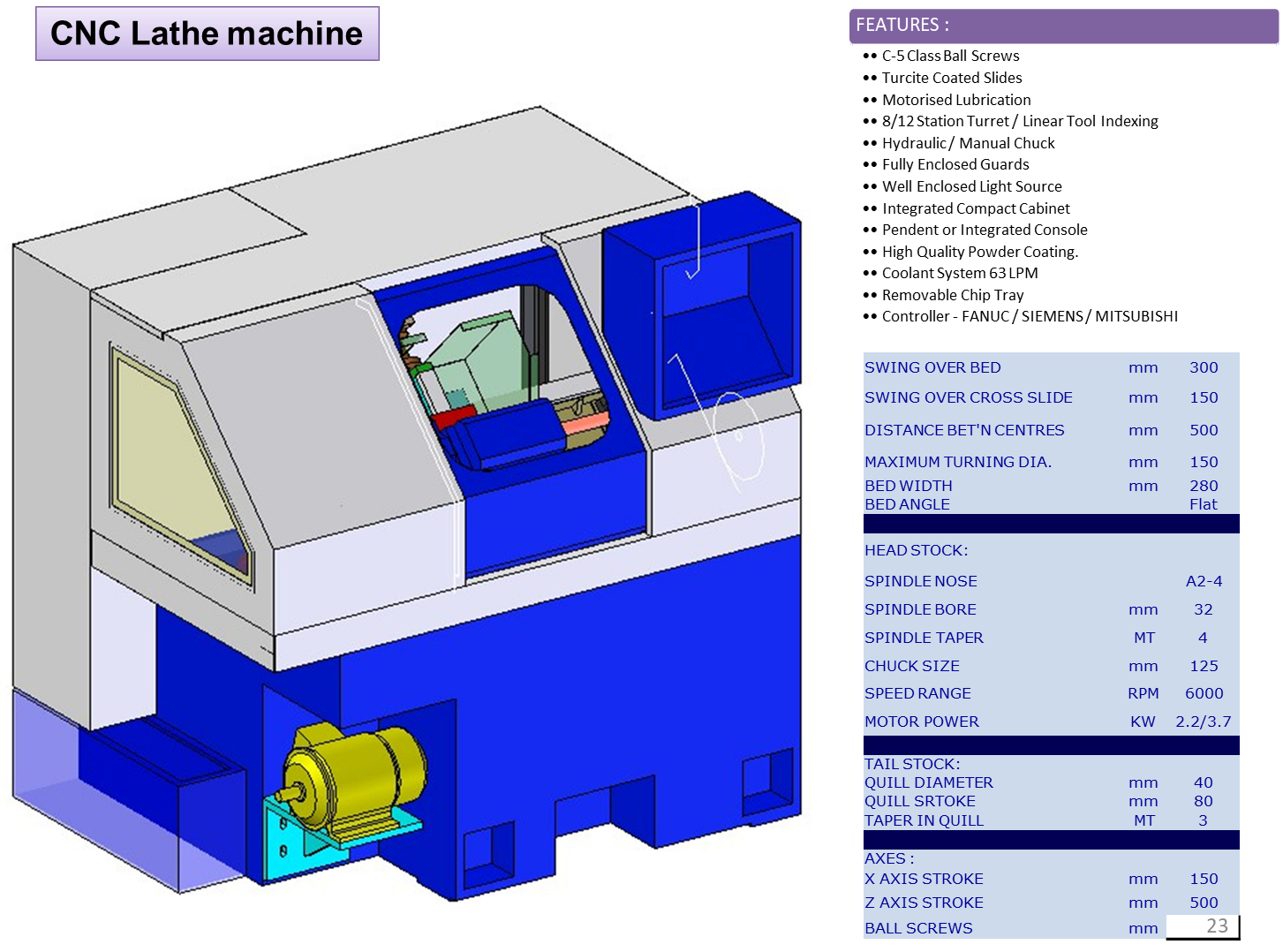

CNC Lathe machine

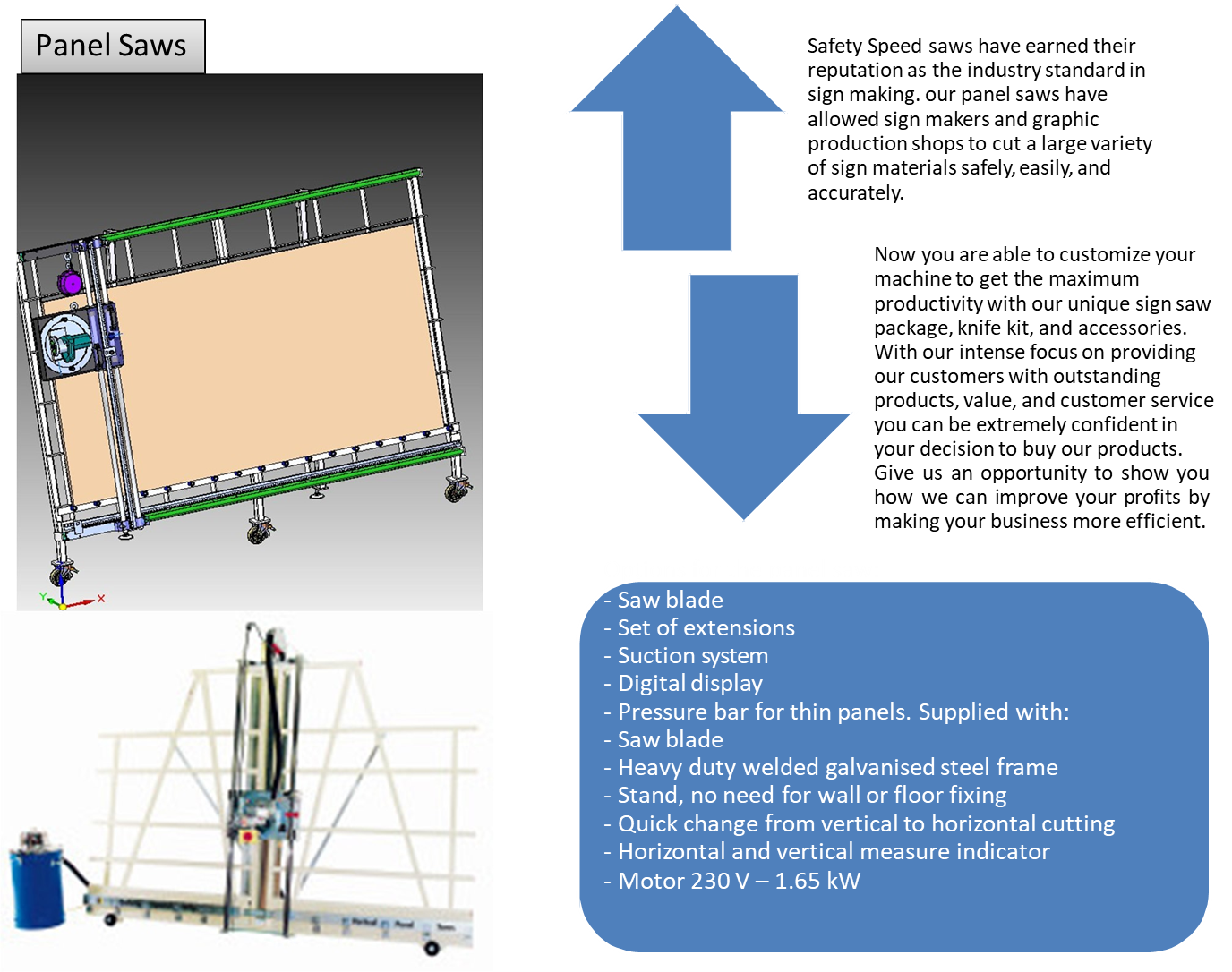

Panel Saw Cutting machine

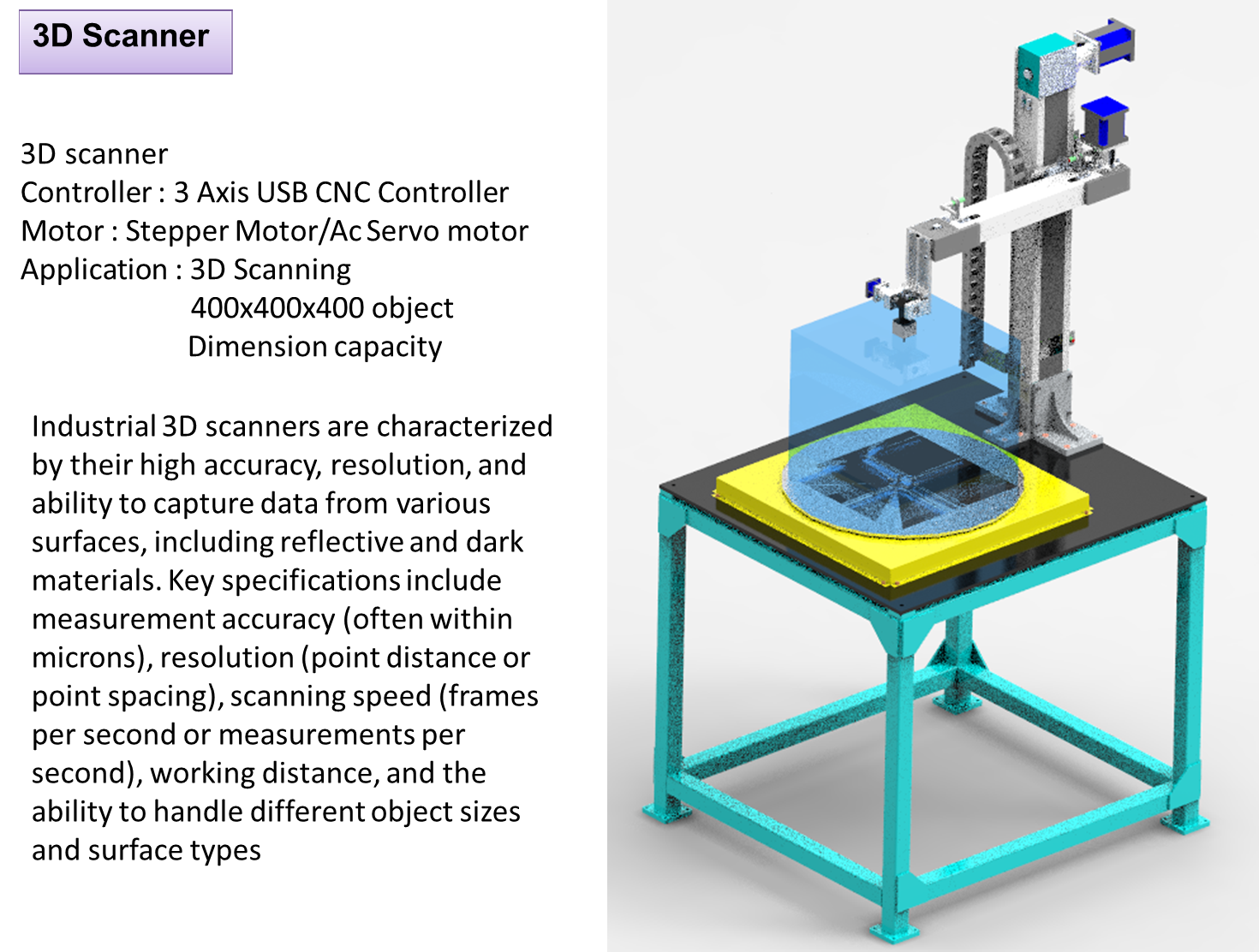

3D Scanner

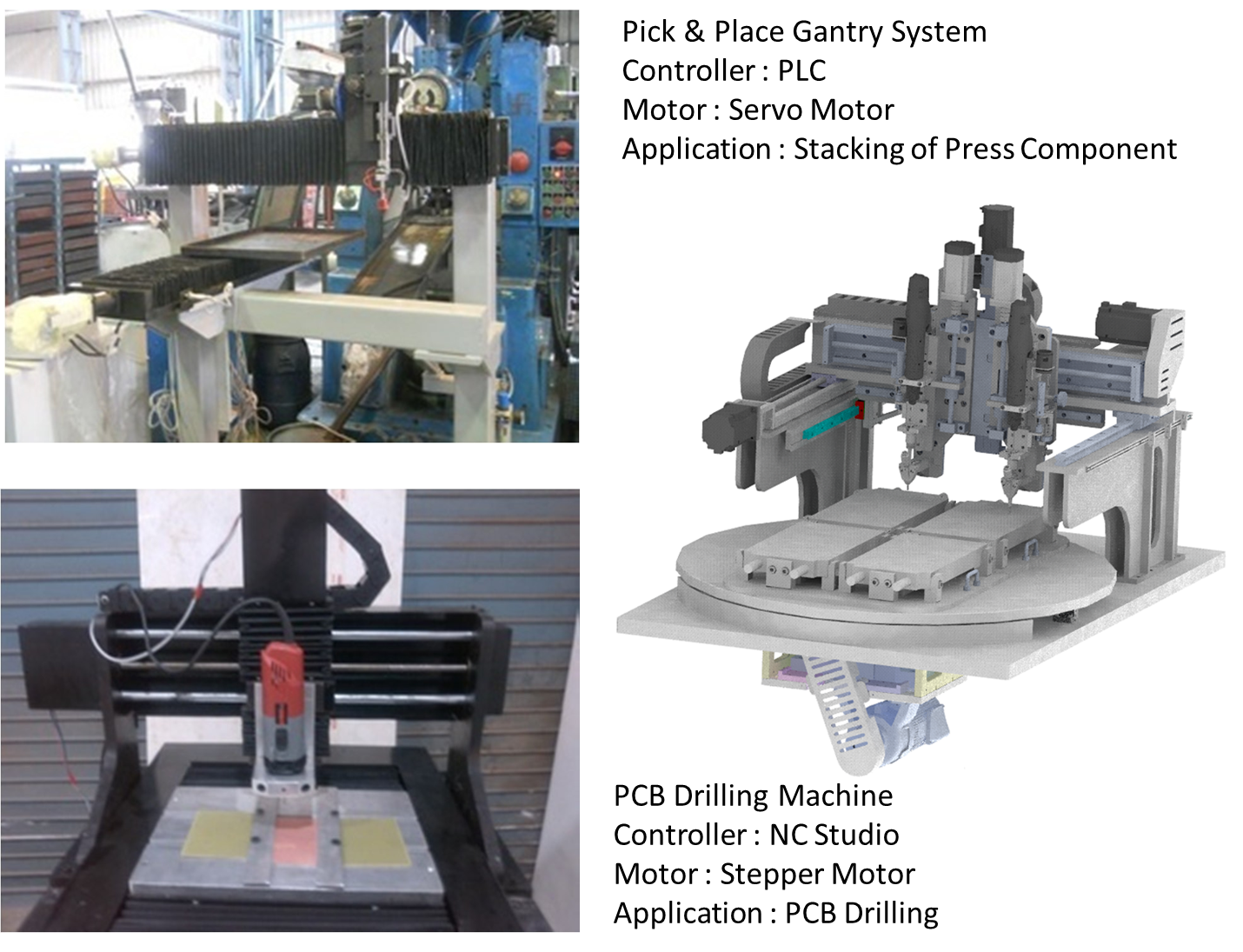

Pick & Place, XYZ Axis,Drilling,

XYZ Axis, Engraving machine

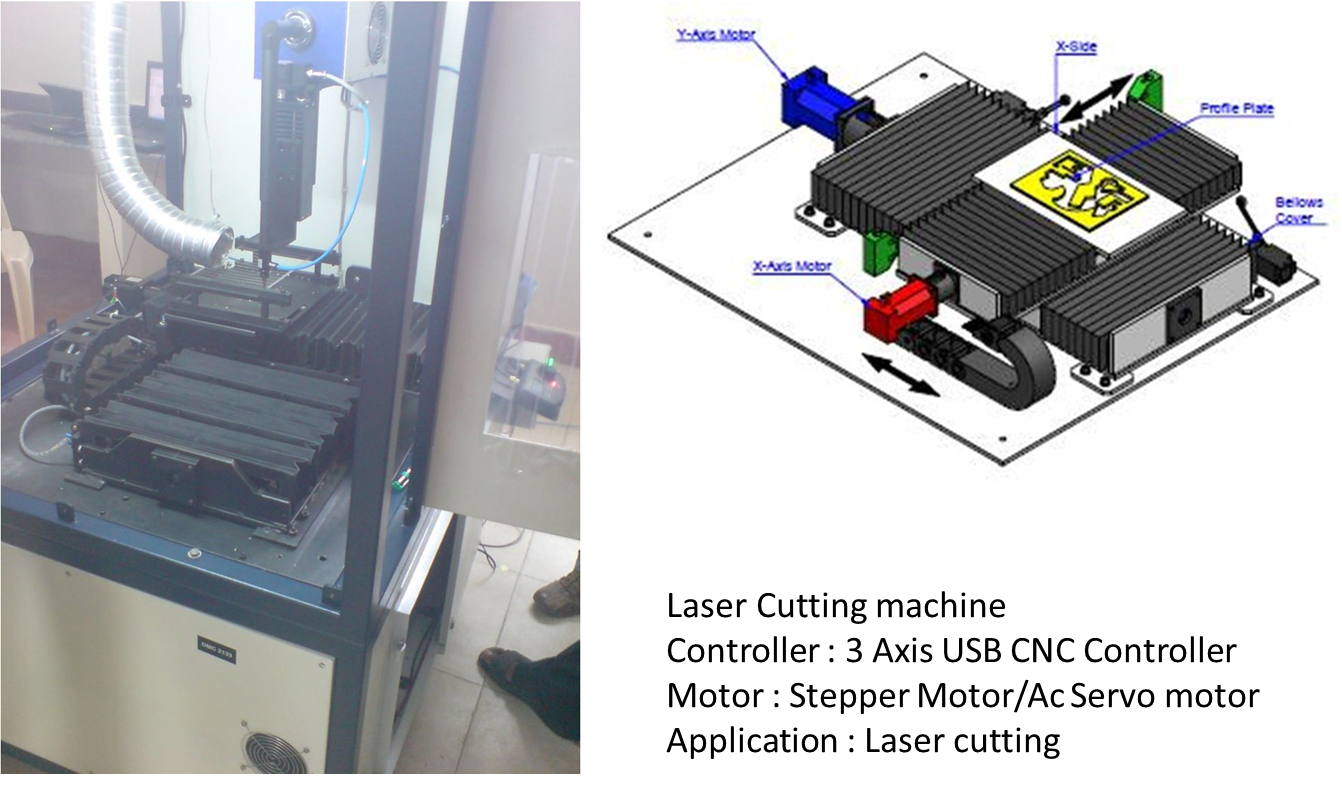

XYZ Laser Cutting

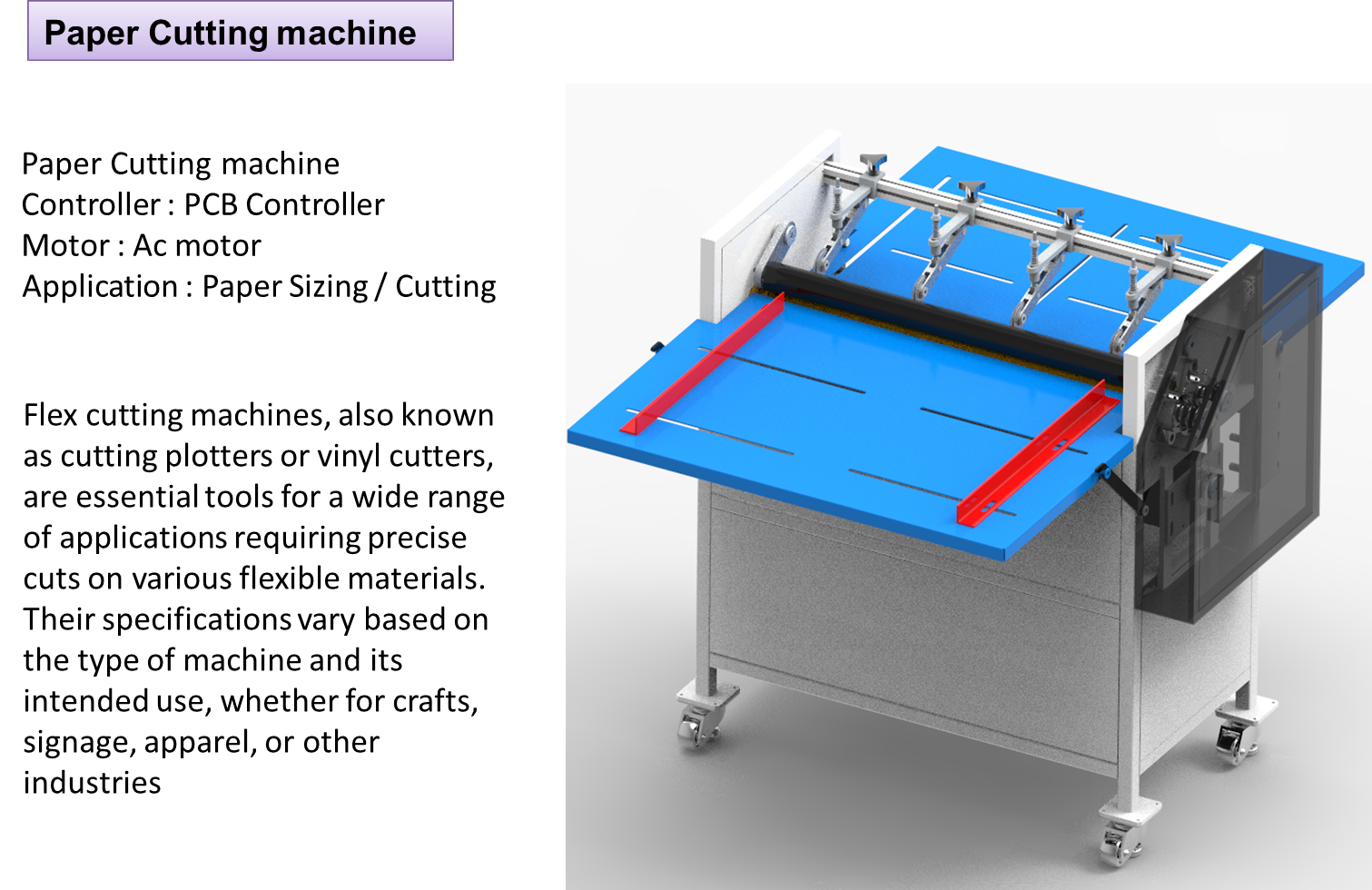

Paper Cutting machine

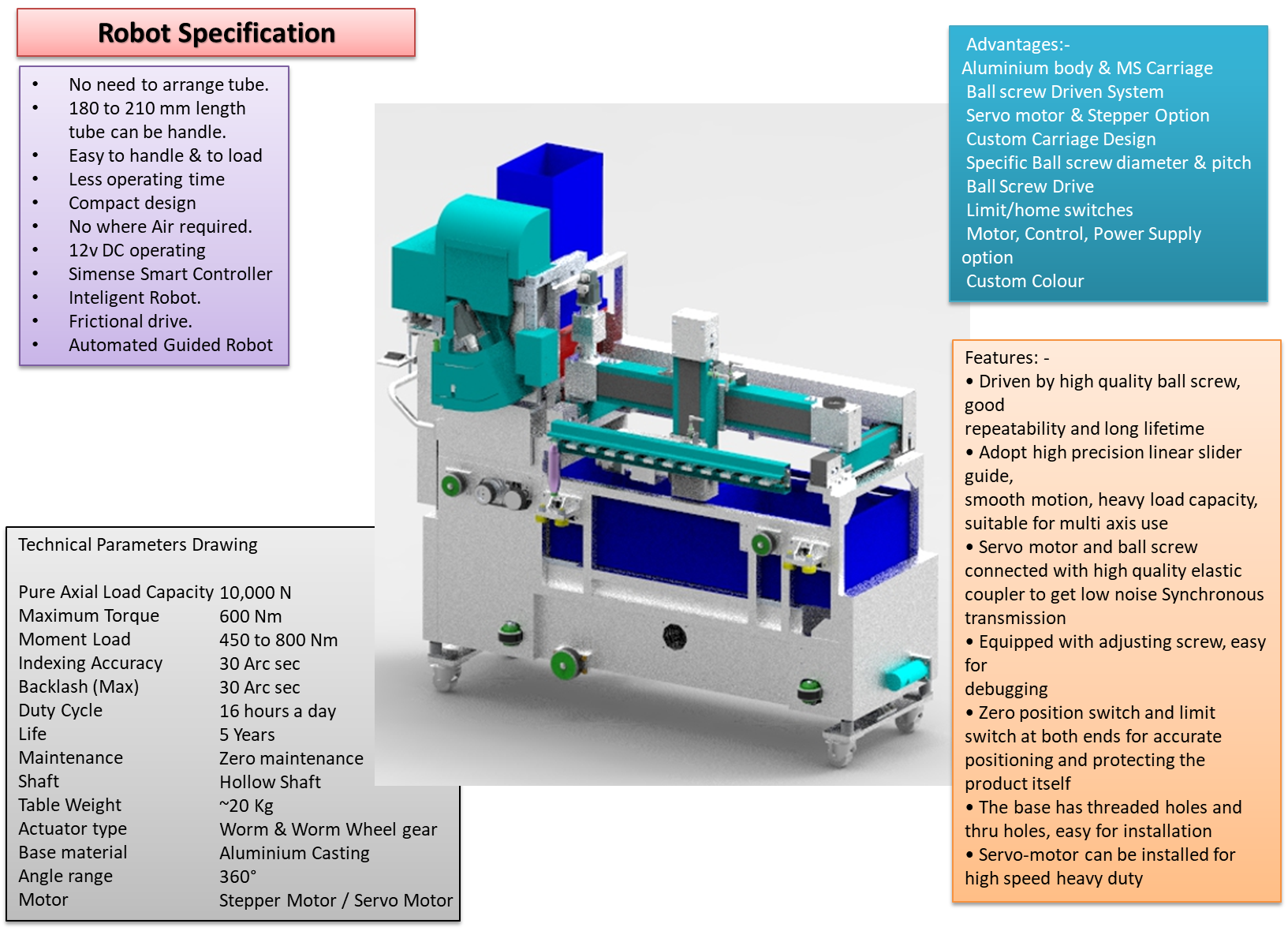

Auto Doffer Robot machine

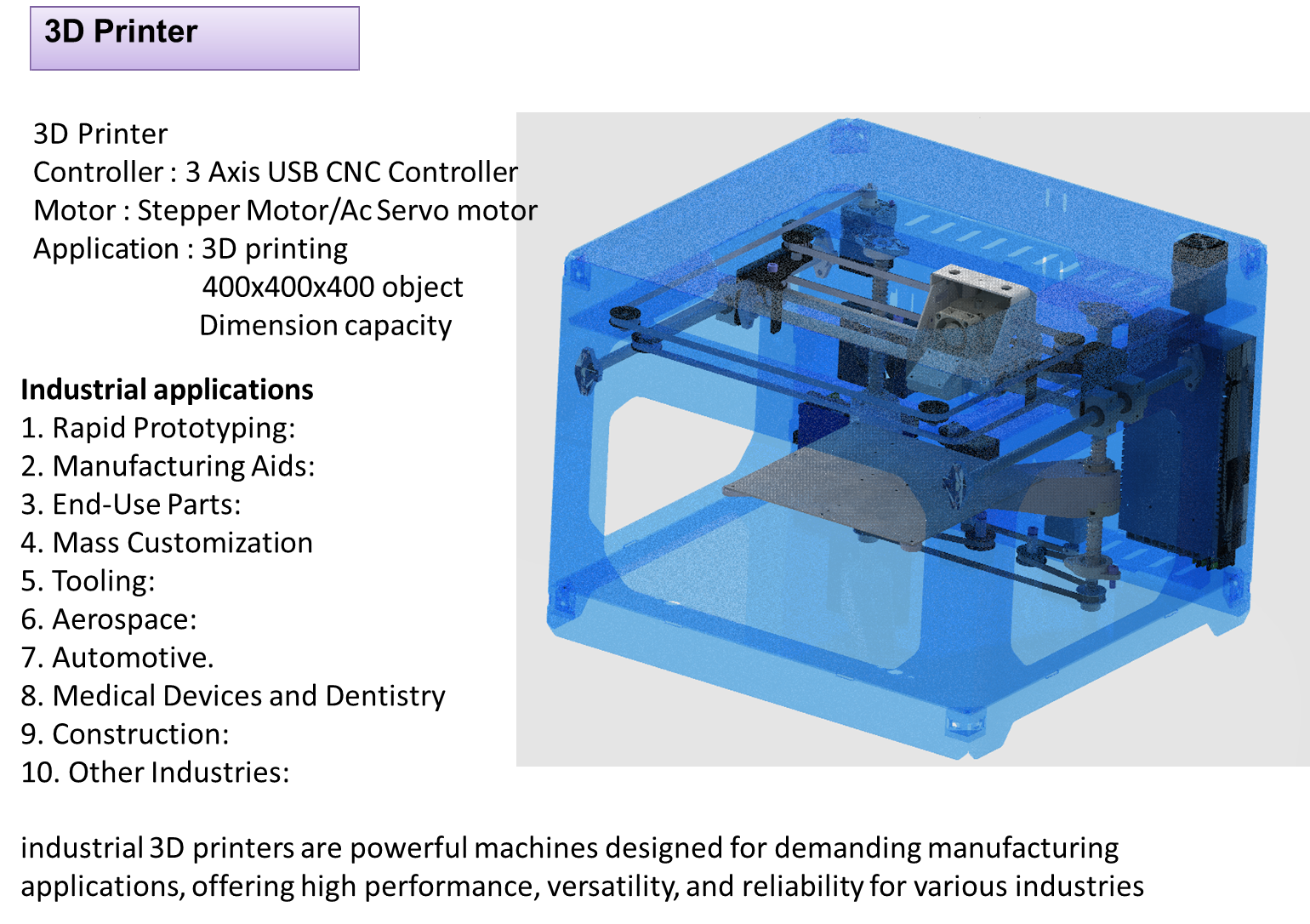

3D Printer

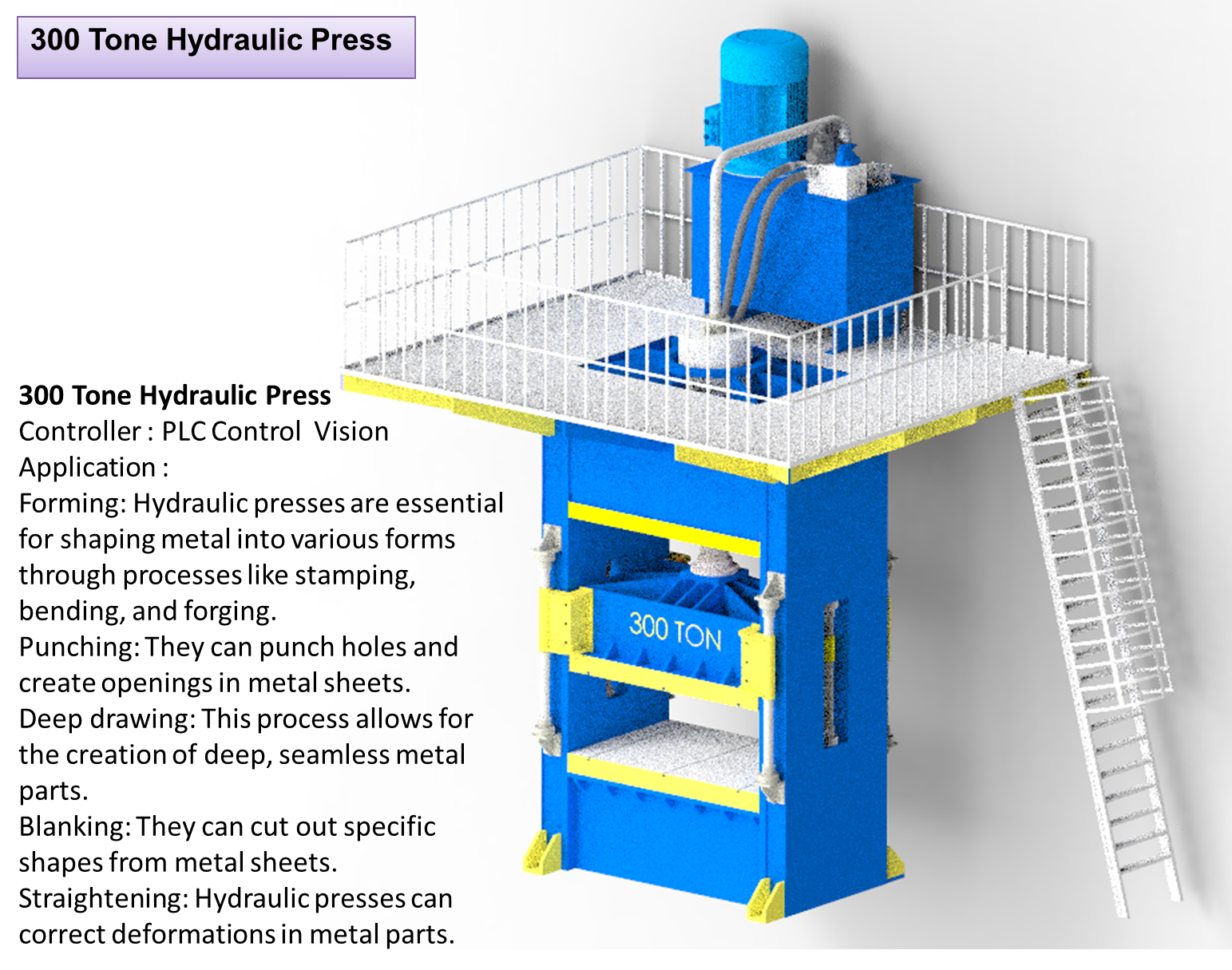

Hydraulic Press

" Industrial Automation & Assembly Lines — Nova-Tech "

The machine design process involves defining requirements, followed by conceptualizing and detailed design, including material selection and component design. This is followed by analysis and simulation to ensure functionality, then prototype testing and validation. Finally, the design is manufactured, assembled, and undergoes quality assurance before deployment.

The design process is typically approached in these seven steps:

- Define the problem. You can begin solving any design problem by asking the right questions. ...

- Conduct research. ...

- Brainstorm and conceptualize. ...

- Create a prototype. ...

- Select and finalize. ...

- Product analysis. ...

- Improve

<< Scroll below, for more slides >>

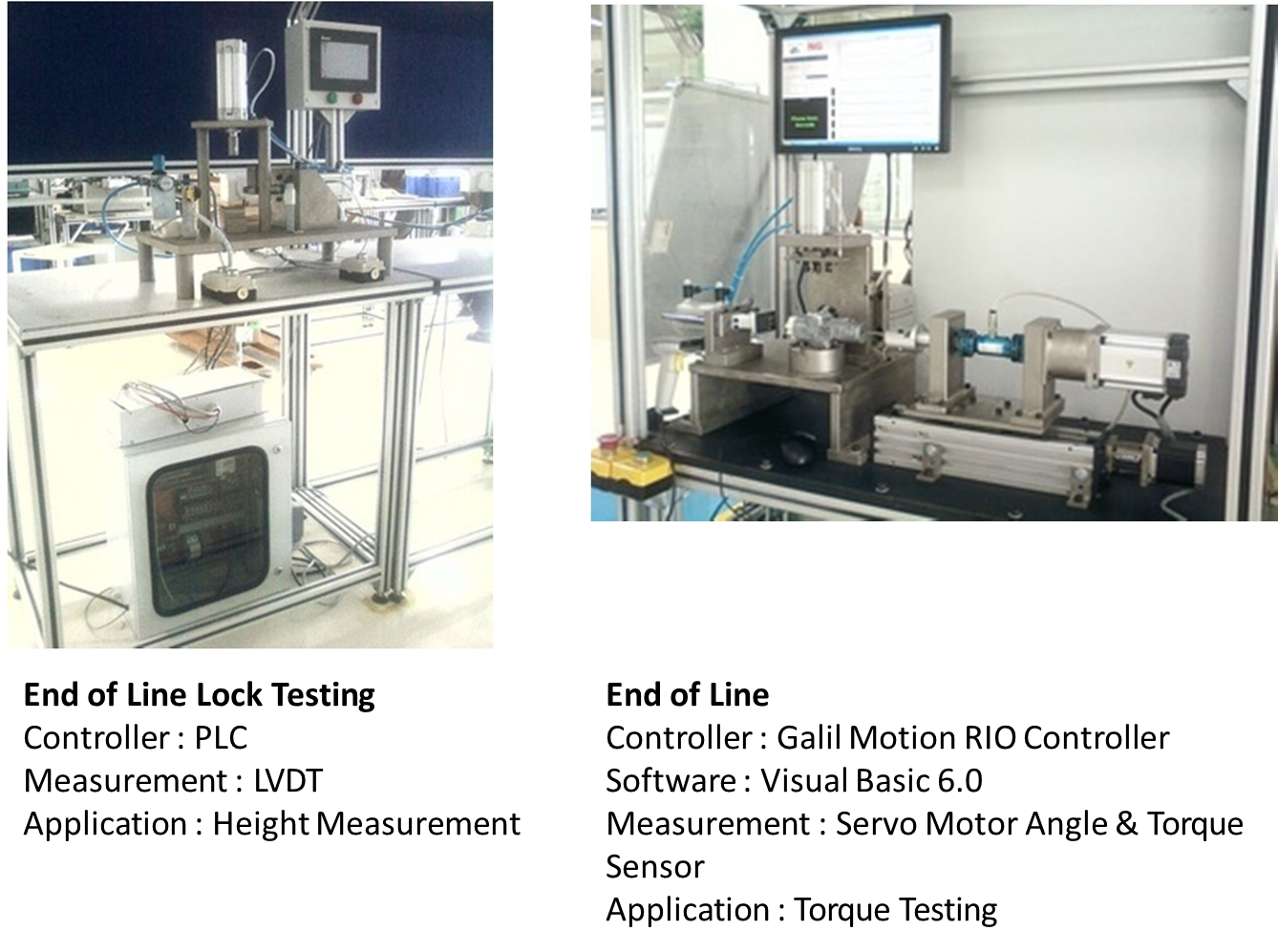

Automobile Lamp operation Testing machine

Automobile Torque load testing End line

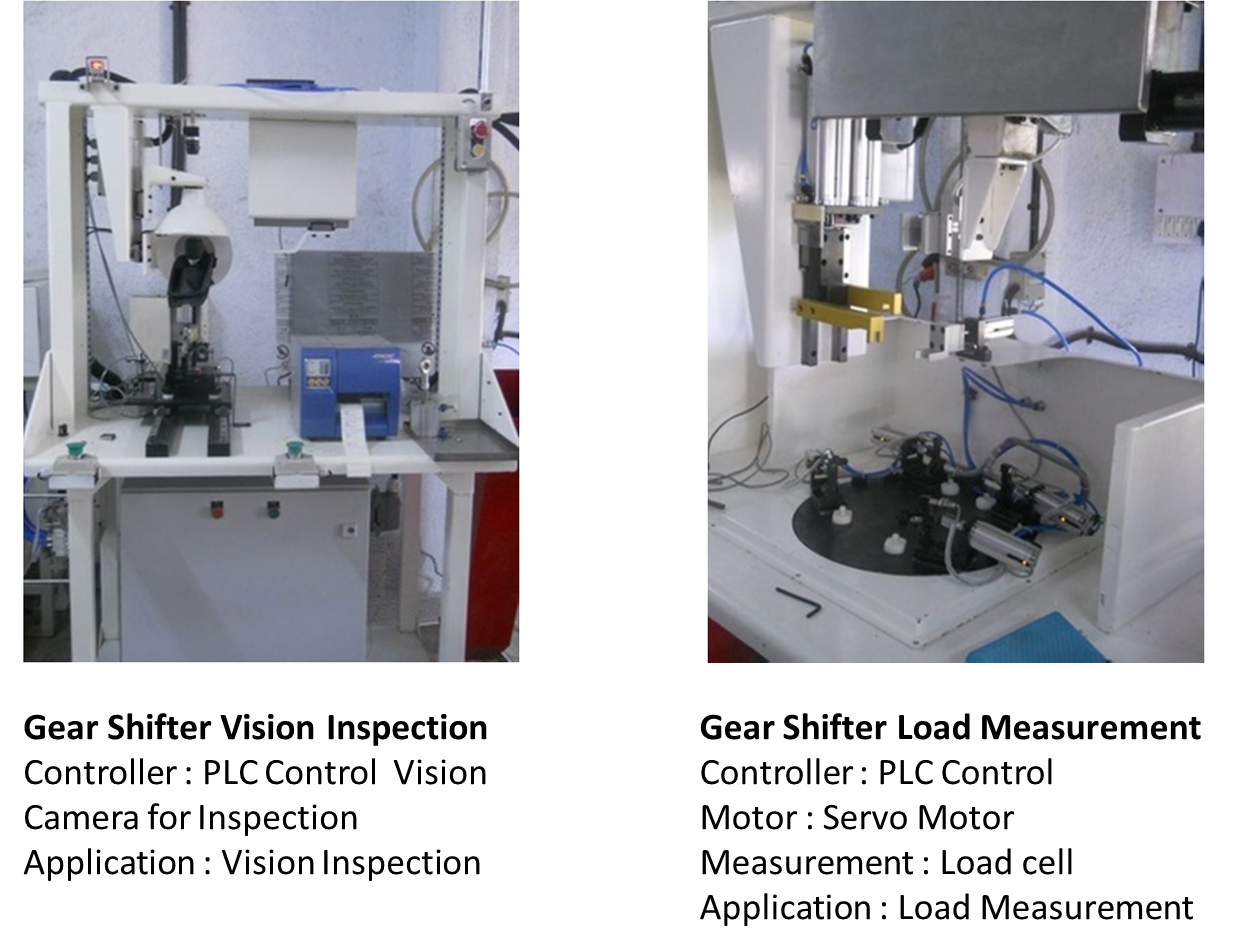

Torque, Load, Operation Testing

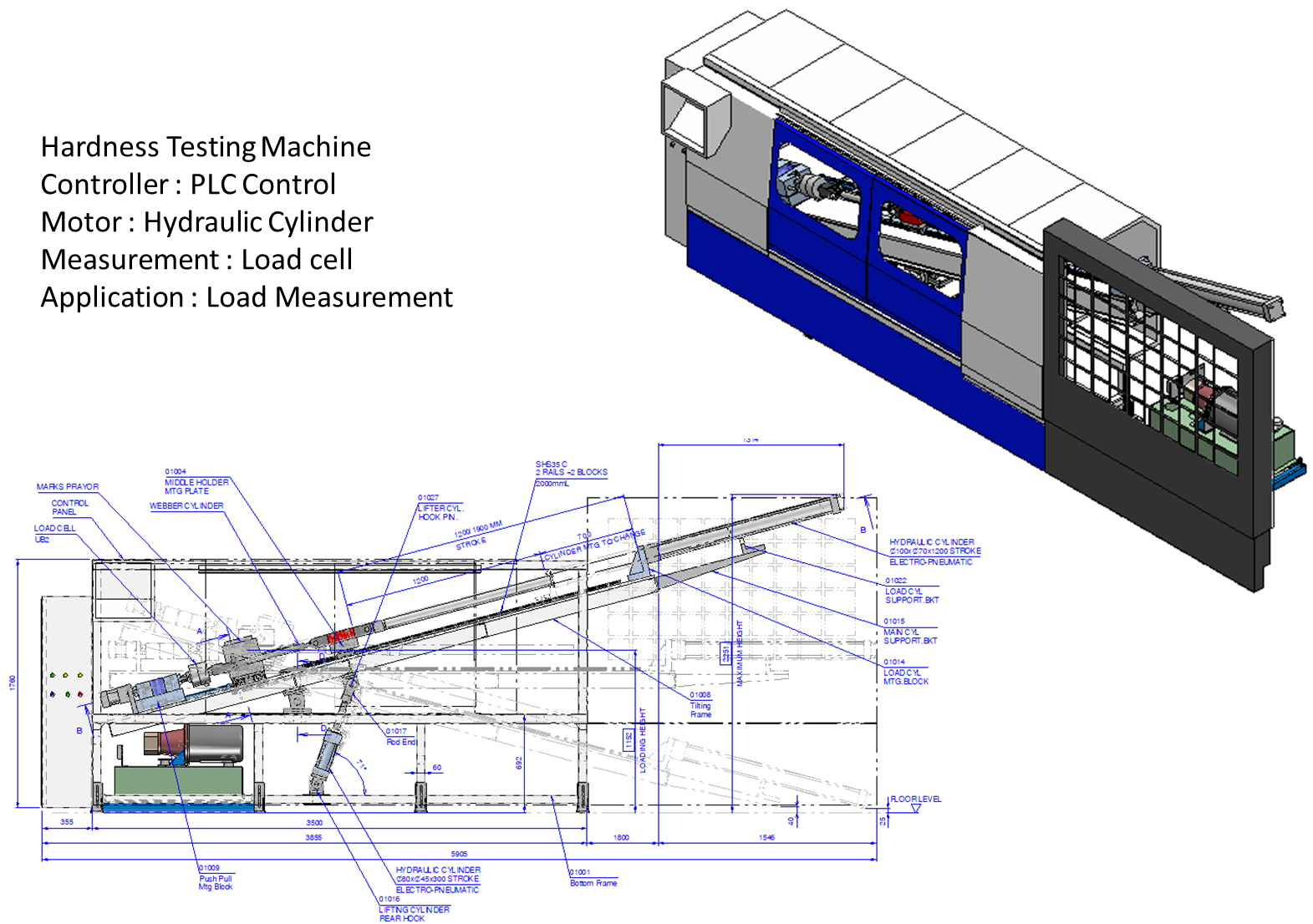

Hydraulic Hardness testing machine

Hardeness testing

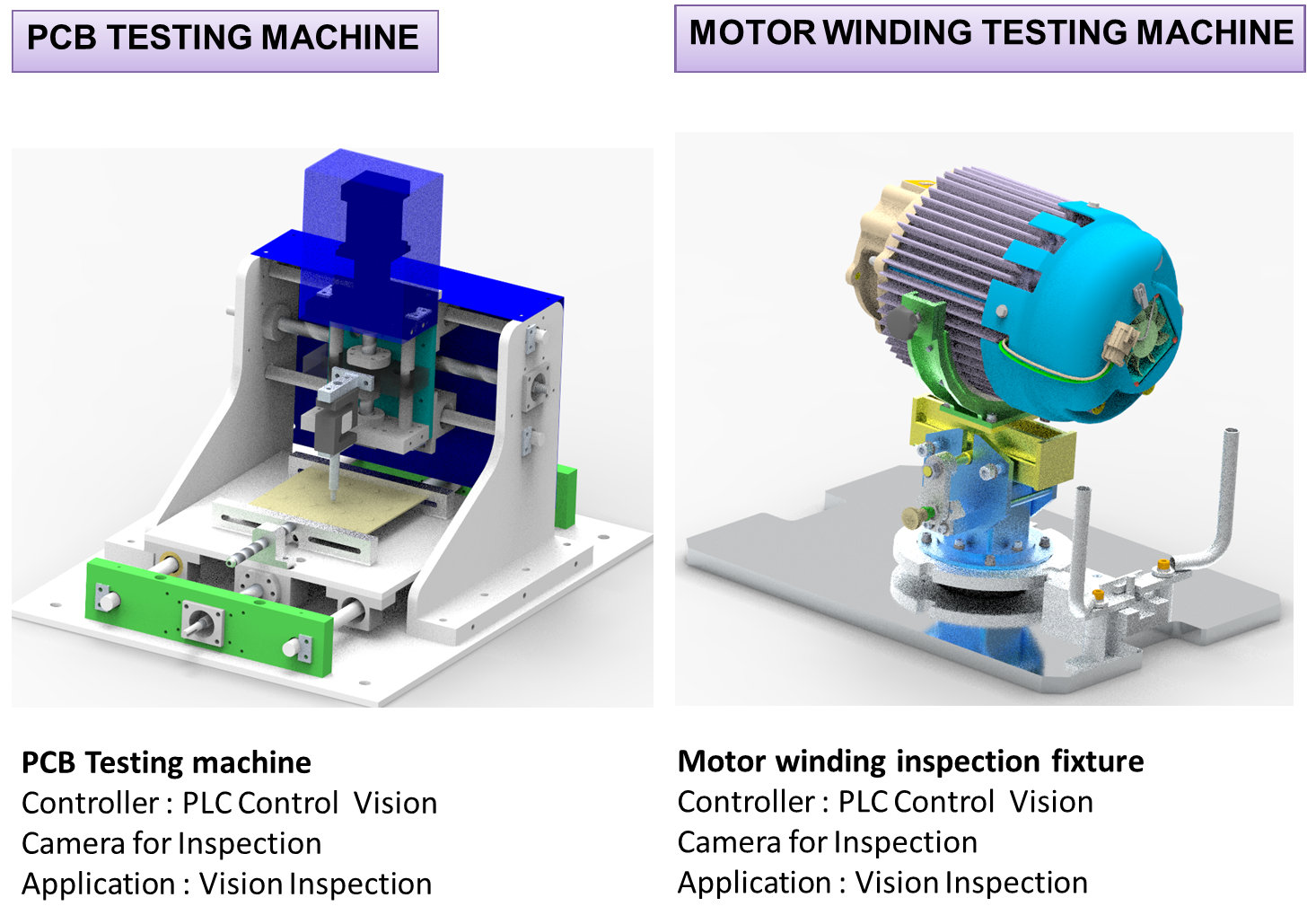

PCB Testing, Pallet Fixturing

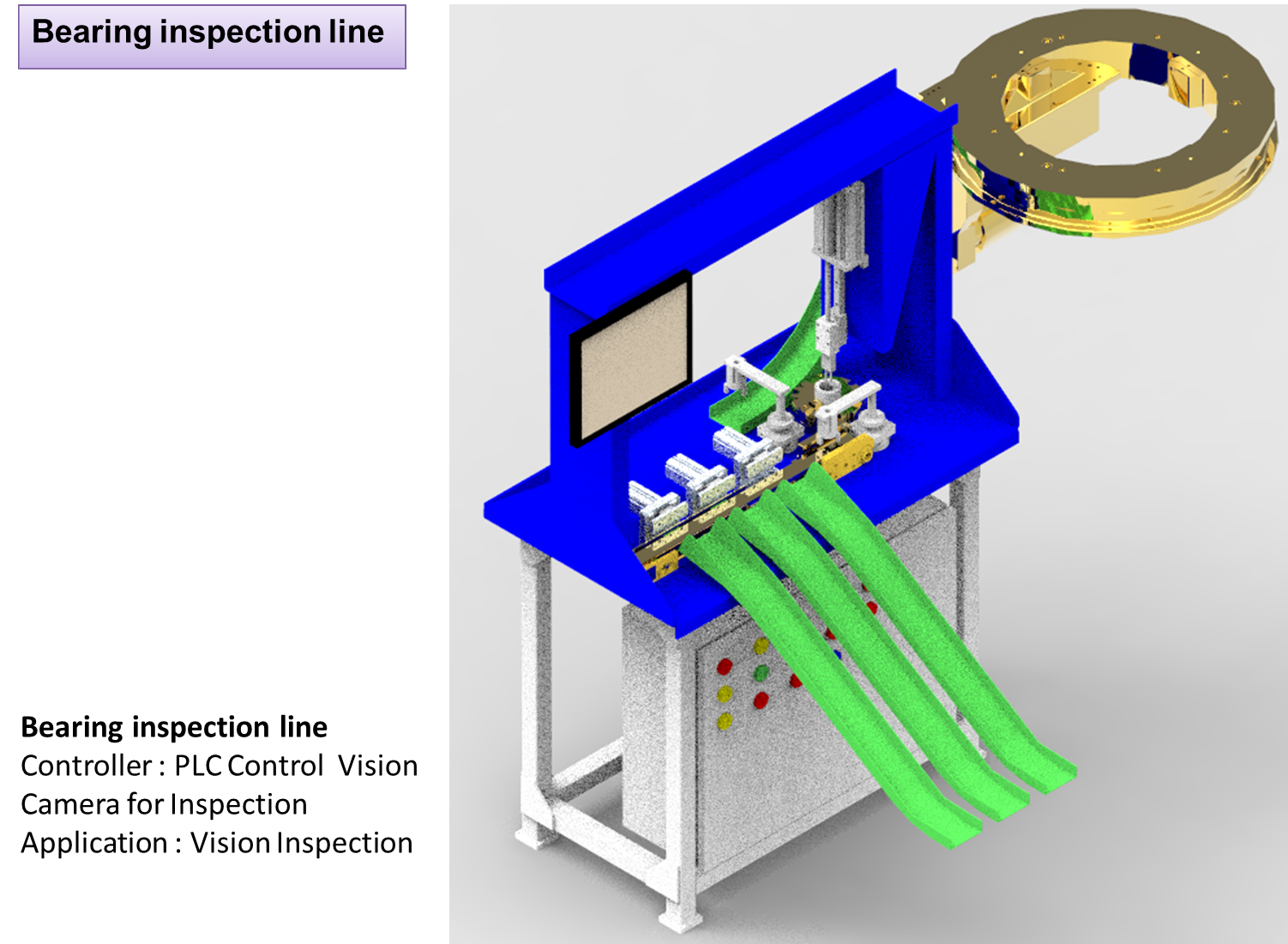

Bearing inspection line

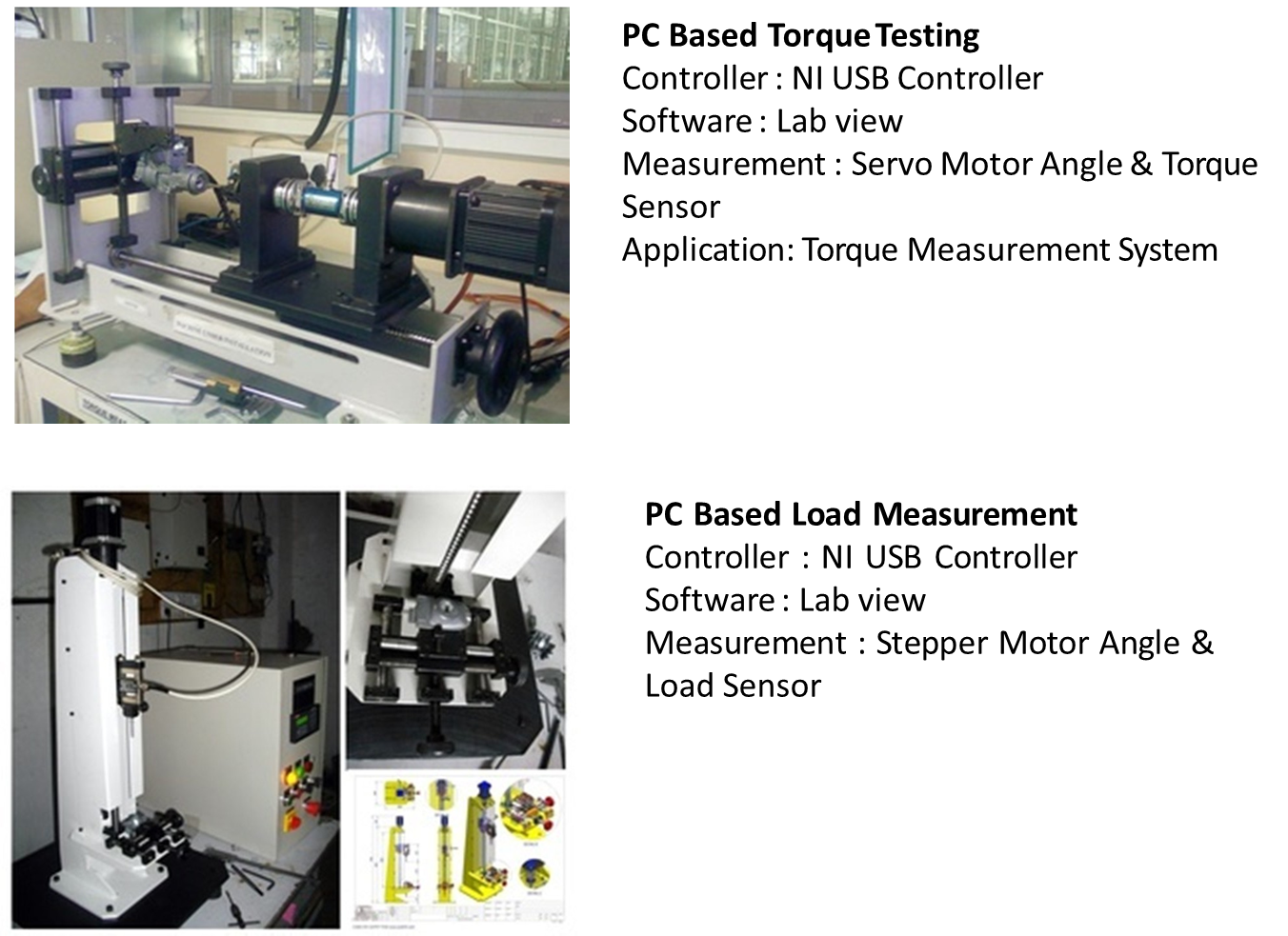

Torque testing, Load testing machine

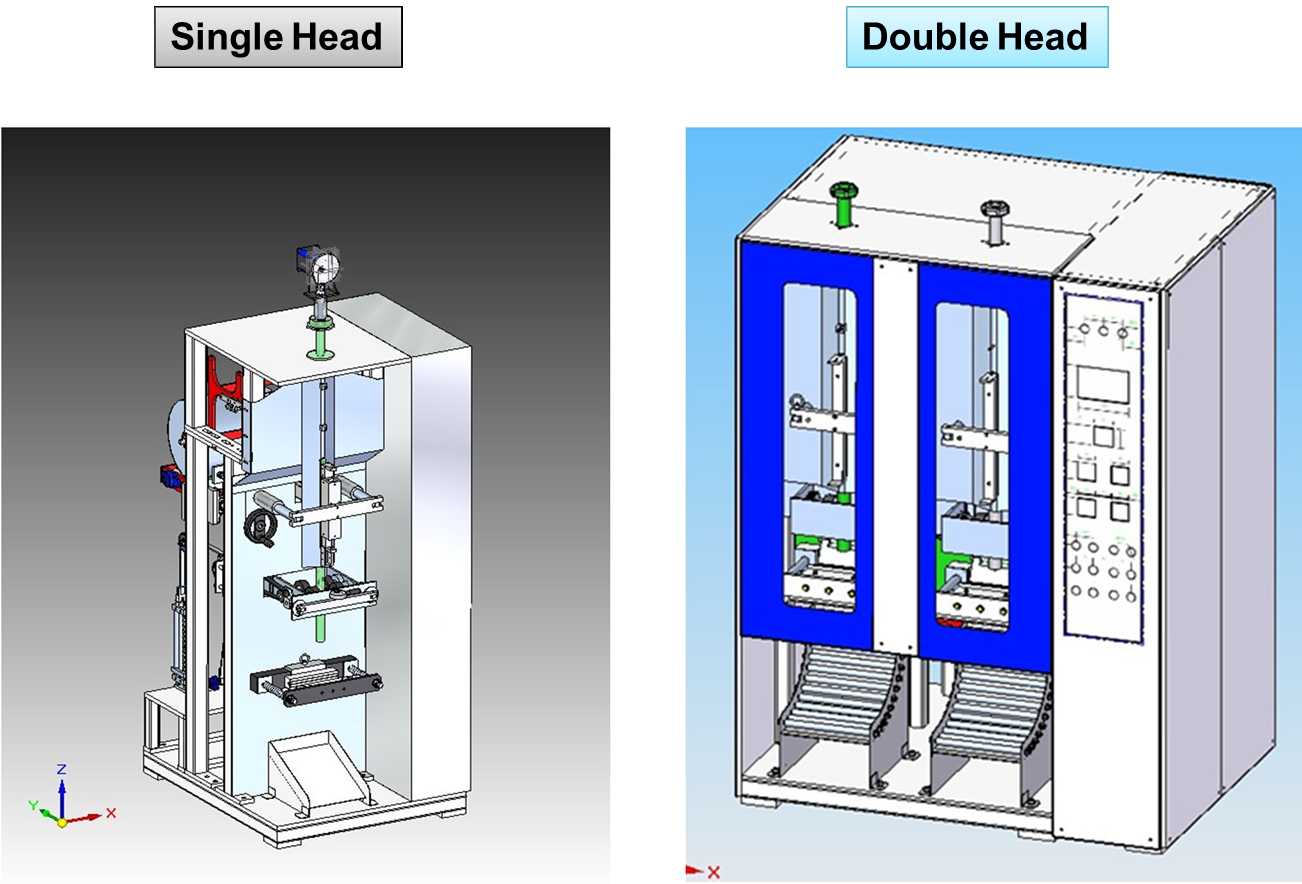

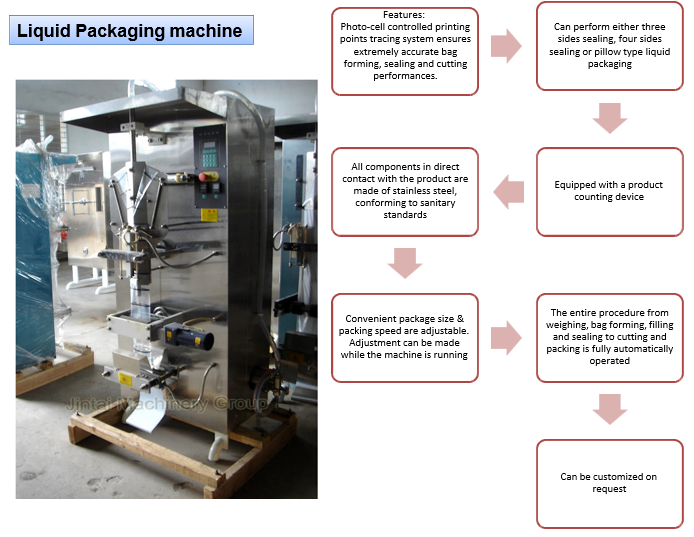

" Packaging Automation — Nova-Tech"

Packaging automation is the use of machinery and technology to perform various packaging tasks with minimal human intervention. These systems, which can range from semi-automated to fully integrated setups, streamline the packaging process to improve efficiency, increase speed, and reduce costs.

- increased efficiency: Automation significantly increases production speeds and throughput, enabling companies to meet high demand more easily. Machines can operate continuously without breaks, maximizing uptime.

- Cost reduction: While the initial investment can be high, automation leads to long-term cost savings by reducing labor costs, minimizing material waste, and improving overall operational efficiency.

- Improved quality and consistency: Automated systems perform repetitive tasks with a high degree of precision, ensuring each package is filled, sealed, and labeled uniformly. This reduces errors and improves product quality.

- Enhanced safety: By automating physically demanding or hazardous tasks, companies can reduce the risk of workplace injuries and create a safer environment for their employees.

<< Scroll below, for more slides >>

Liquid Packaging machine

Milk packaging